Product Configurator hits the ‘Suite’ spot for Finline Furniture

Established in 1979 Finline Furniture has become the leading Irish manufacturer of high-end bespoke furniture. From its factory in Laois, Finline export their products all over the world. Explore below why EFACS is the suitable ERP for furniture manufacturers.

Customer Profile

Finline Furniture was established in 1979 to manufacture high-end furniture for the wholesale market in Ireland and the UK. Over the past 10 years it has expanded into selling directly to the consumer through its network of Irish showrooms.

The Challenge

The current system was unable to keep up with the needs of the business and there were limitations surrounding manufacturing and design. There was also a massive amount of document and input duplication happening throughout the business.

The Solution

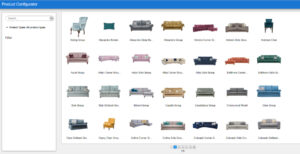

EFACS was chosen as it is an ERP system designed for manufacturing. EFACS’ product configurator module offered the company a streamlined automated process from design to manufacturing and delivery.

The Benefits

Elimination of paper, automation of processes and digitisation of the business allows Finline Furniture to grow without increasing staffing levels.

Over the years the business has evolved from initially being a wholesale manufacturer supplying to businesses such as Arnott’s, Brown Thomas and Casey’s in Cork as well as throughout the UK.

In the early noughties the decision was made to open their own showrooms and sell directly to the consumer. They have showrooms in Dublin, Cork and Galway as well as the factory in Laois. They focus on the manufacture of high-end bespoke furniture where the customer chooses the fabric, style and finish and it is then made to order.

The existing system was an old bespoke system designed specifically for the furniture manufacturing sector. Over the years with the business model changing away from standard manufacturing and more to bespoke one-off manufacturing, Finline recognised that their existing solution was no longer fit for propose. Early on they identified the requirement for a Product Configurator. There was also a huge amount of duplicate entry of sales orders from all the external showrooms. These factors, together with the fact that support for existing software was declining from year to year, led them to realise that they needed to change. As MD Kilian Finane explains: ‘ERP Head-to-Head was the first time we met Profitsflow. We attended the event to look at what systems were out there and from the start we ruled out the Tier 1 providers as we felt because of our size and the bespoke nature of our requirements we needed to work with someone who could be flexible as a solution provider. We needed someone to work with us in understanding our business. Also having a good level of local and easily accessible support was very important to us. Price and value for money were also very important factors. As Profitsflow are a local company and could be on site quickly if required was a key factor in our decision. Also, the fact that Profitsflow wanted to come down and see our factory and our existing processes before they put a proposal together was important to us. Having spent time with the Profitsflow team during the selection process myself and my team felt that they were the best fit for us. Obviously, price was also a key factor.’

The flexibility that the product configurator offers was a big factor. With that flexibility comes the requirement to learn how to use it properly in order to get the best out of it. The benefits of all the works orders being created automatically and the components being ordered seamlessly has allowed Finline to completely digitise their business, which has led to huge savings in administrative duplication. The configurator has given them a much greater level of accuracy and flexibility. Building the configurator in the way that they did gives their customers a blank canvas to give them what they want. This was a key requirement for Finline Furniture.

Along with the product configurator the other must have during the selection process for Finline was an integrated accounts package. So, the automatic transfer of sales orders and posting of invoices and updating of ledgers etc. was critical to the success of the project. Once the sales order comes in from the configurator the works order can be automatically generated and the components ordered.

In Finline’s case, if a customer orders a plain fabric, we would need say 12 metres of fabric, but if they order a patterned fabric, it might be 15 metres required. The software allows us to build in expressions to determine automatically how much needs to be ordered. This gives them huge benefits as they don’t have to go through each order individually and add the total required. The MRP module accumulates the requirements and turns the process into an over seeing role rather than a laborious task.

The parts module allows them to flag components with different re-order policies such BTO (buy to order). On running MRP all this is calculated and suggested orders are created awaiting approval. This automation has led to much greater improvements in efficiency and accuracy.

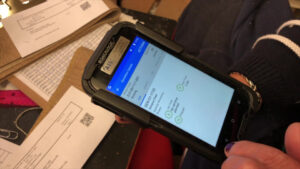

Another option that Finline were looking for, was transparency in the production process. With EFACS you can now see at what stage every order is at, e.g. what workstation it has gone through, has it been cut, sown, upholstered etc? The process can take a number of weeks so it is very important to know where it is, at any given time. Scanning the works orders through each work station gives them instant feedback as to what has been completed and what is still outstanding for the works order.

Kilian has described the benefits of EFACS as follows:

“The big wins are moving from handwritten dockets to a digital system, which allows for more consistency in how we discuss things inhouse, especially in the terminology different people would use. In terms of sales, we feel it is now far more a professional and polished service we are giving our customers, from the initial quotation to how we communicate the order confirmation and indeed all our customer documentation. As well as being a far more professional methodology, it also has the major benefit of the information only being entered once and everything else happens seamlessly. The remote showrooms now have direct access to sales orders which is hugely beneficial to all our sales staff. Along with having instant access to what lines are selling best and in what fabrics etc. I suppose what I am really saying is having instant access to real time information allows us to make informed decisions on business strategies.

On the manufacturing side, the fact that the processes are more automated and that there are built in controls around stock levels leads to greater efficiencies in stock control. This subsequently gives us improvements in cashflow and storage capacity in the factory.”