Achieving the optimum stock holding is critically important for the viability and profitability of any business, but weighing the competing forces of customer demands versus supplier lead times is particularly troublesome for manufacturers. As the business grows, it becomes gradually more difficult over time to marry the long lead times associated with importing parts, components and materials from the far East to the days or even hours dictated by customers. And none of this takes account of the time it takes to manufacture! However with some planning, there are answers. Try to avoid the short term solution of over-stocking which can literally gobble cash flow. Some tips:

Don’t over-rely on suppliers

Where possible have up to three alternative suppliers for every product. One should be local (often will be more expensive but short lead time). The others should be lower cost and have agreed quantity break discounts.

Forecasting

Try and get a forecast from your customers. Even if it is only 80% accurate, that’s a whole lot less firefighting you have to do. Even better, if you can manage to get them to agree to a call off schedule over time – you can build commitment horizons into the contract to ensure that once you have ordered your materials, the customer commits to cover the cost.

Your business model

Do you manufacture to order, sell from stock? Is Just in Time required by customers? Have you looked at the breakdown of your customers’ orders lately to assess whether you are following the correct model (correct for you, not necessarily your customers!)

Your capacity

Even if you have the materials and parts needed in stock, do you have capacity to manufacture in time to deliver the commitments made to your customers? If, like so many manufacturer’s, your production manager is literally firefighting every time a new order comes in, capacity and production flow needs to be looked at.

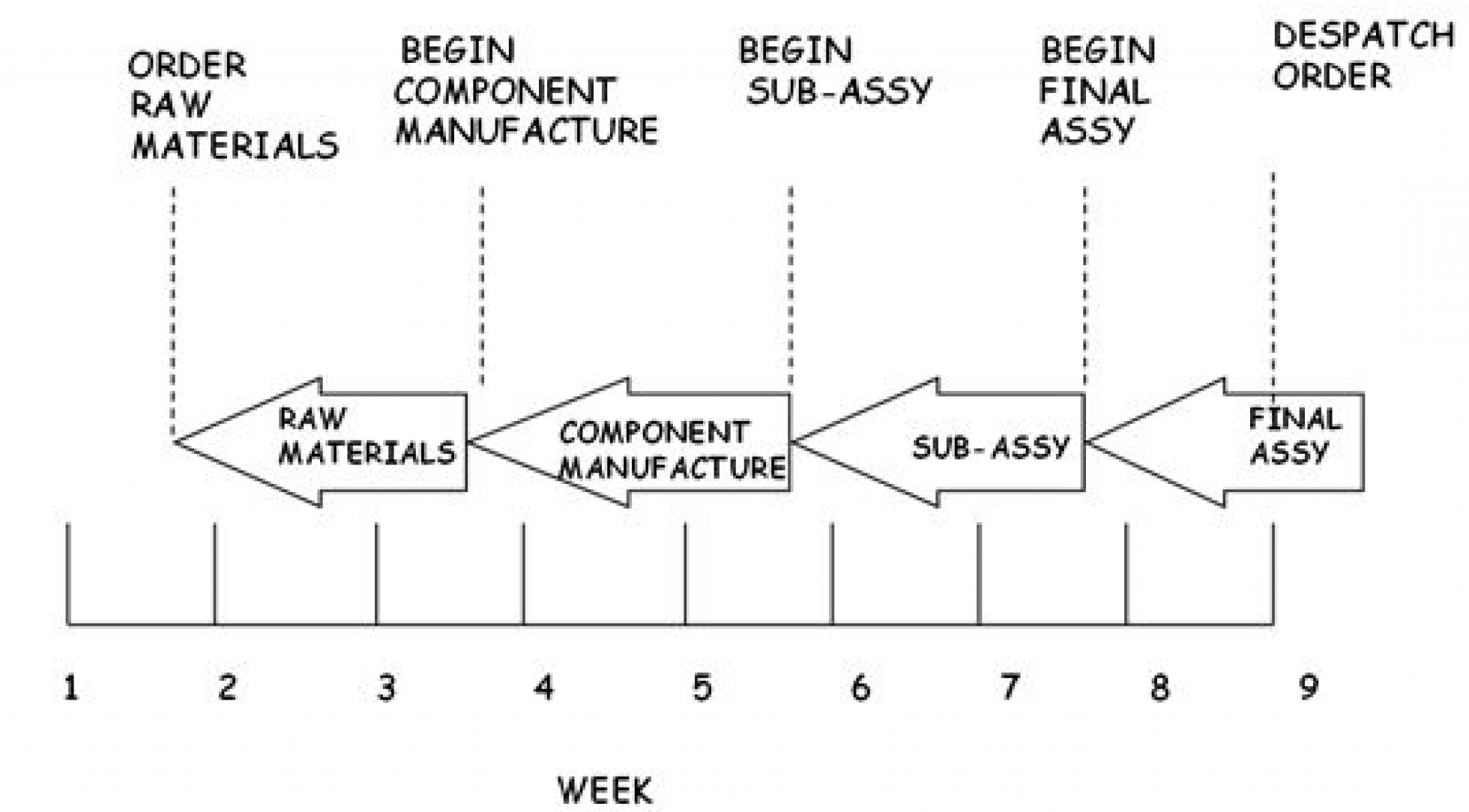

The solution: Materials Requirements Planning (MRP) and Materials Resource Planning (MRP-II)

For smaller businesses, the above issues can be managed to a point using office tools – e.g. Spreadsheets, databases, etc. However as the business grows more advanced planning tools will bring a level of efficiency that will pay for themselves many times over through the course of a year. Implementing Materials Requirements Planning allows you to achieve the following:

Assess customer requirements

Review sales forecasts and nett off customer orders for the products and periods in question

Evaluate and consolidate supply requirements

This is where it starts to get complex. For manufactured product, the Bill of Materials (BOM) is exploded, and material requirements obtained. These requirements are assessed against existing stock and current purchase orders. Each item has a consolidation window – requirements for dates within this window are accumulated. Finally order rules such as minimum order quantity, batch rounding quantities, etc. are applied.

Choose the correct supplier

An assessment of the required timeframe and pricing is used to determine preferred supplier.

Materials Resource Planning (MRP-II)

To get to a true planning conclusion, it is necessary to feedback information from the capacity planning tool, which supplies MRP with the expected completion date and therefore anticipated stock levels of each sub-assembly.

Find our more in our new White Paper: Cash in some stock with Materials Requirements Planning